Inventory Shrinkage Guide: Detect & Prevent Losses

Inventory shrinkage is a common issue for retailers. It can lead to a drop in profits and require you to alter your accounting books, which will cost you even more time and money to fix.

To combat significant inventory shrinkage, you must familiarize yourself with what it is, why it happens, and the preventative actions you can take. Let’s take a look at inventory shrinkage and what you can do to avoid it.

So, what do you want to learn?

Request Fulfillment Pricing

Let’s talk. Our experts can help you boost your order volume by 30% year over year.

A fulfillment expert will get back to you shortly. Privacy Policy

What is inventory shrinkage?

Inventory shrinkage is when actual inventory levels are less than recorded inventory levels.

In other words, inventory shrinkage occurs when your physical inventory count does not match the amount of inventory you recorded. Usually this means something has gone wrong, either from an accounting error, damage, or theft.

Why you should calculate inventory shrinkage

Nobody wants to think about inventory shrinkage, but businesses can’t afford to ignore it.

Like most other business losses, inventory shrinkage impacts your bottom line. For every piece of inventory that’s unaccounted for, you’re essentially throwing away money or losing product – so to ensure that your business stays afloat, it’s critical to keep tabs on how much of your resources you’re losing.

Even more importantly, calculating inventory shrinkage is key to minimizing it in the future, as an accurate calculation could give you a hint as to the shrinkage’s cause.

For example, if your inventory shrinkage percentage is consistently low, a sudden spike is probably just the result of a simple miscalculation. However, if it is always high, you should begin considering other, more nefarious causes, like shoplifting, employee theft, or vendor or supplier fraud.

How to calculate inventory shrinkage rate

In order to discover precisely how inventory shrinkage has affected your business, you’ll need to calculate, track, and monitor it over time.

You can use the following formula to calculate your inventory shrinkage rate:

Inventory Shrinkage Rate =

(Recorded Inventory – Actual Inventory) / Recorded Inventory

Then, multiply your inventory shrinkage rate by 100 to convert it into a percentage.

Let’s walk through an example:

Let’s say you recorded $70,000 in inventory value. Your cost of goods sold is $28,000. Your inventory’s book value should be $42,000 ($70,000 – $28,000).

However, due to shrinkage, you discover that the actual value of inventory is $63,000. You then use the inventory shrinkage rate to find out how much value you lost:

Inventory Shrinkage Rate = ($70,000 – $63,000) / $70,000

This equals 0.10. Multiply 0.10 by 100 to show inventory shrinkage as a percentage: 10%.

Your inventory shrinkage rate is 10%, which means you lost 10% of your inventory value to shrinkage.

How does inventory shrinkage impact ecommerce businesses?

Accounting for inventory shrinkage is crucial to growing your business. Without knowing where your products are going, you can lose out on profits, risk misrepresenting your value on accounting reports, and increase your cost of goods sold.

Loss of product

The most obvious problem with shrinkage is that inventory gets lost and can’t be retrieved. This means you don’t have them on hand to sell, or even to repurpose in some other way.

Money thrown away

Every piece of inventory that is lost is money down the drain. You already invested funds to obtain the inventory in the first place, and if you no longer have the inventory on hand to sell, you will be unable to recoup that investment or make a profit. This cost can affect other aspects of your business, such as your hiring capacity, expense management, and more.

Accounting and tax miscalculations

If your inventory records and sales records don’t match, you will have to spend a significant amount of time reconciling your receipts and accounting records. If this information is full of errors, the IRS can get involved and potentially audit your business.

“ShipBob is our source of truth for shipping data. I also love the analytics tools, and so do my accountants. I can also see how my team is doing, tracking their order metrics as they fulfill orders. While we now pay for our own rent and the salaries of our fulfillment center team, we have been able to save 10% and reinvest that into other parts of the business. It’s been game-changing, while still having ShipBob be a part of our ecosystem.”

Courtney Lee, Founder of Prymal

The 4 main causes of inventory shrinkage

There are plenty of root causes of inventory shrinkage, which will vary for brick-and-mortar and ecommerce businesses. Here are four of the most common causes of inventory shrinkage.

1. Consumer theft

Also known as shoplifting or external theft, this happens when someone comes into your physical store and steals a product. Depending on the type of products you sell, theft can be easy to prevent (locked cases, ink tags, etc.), or may require manual, psychical surveillance for smaller, less valuable inventory items (food, produce, etc.)

2. Employee theft

With direct access to all of your products, employees may be capable of stealing from your inventory. While you’ll want to hire employees you trust, you will also want to find ways to prevent internal theft (e.g., proper warehouse management and security) and learn how to handle it when it occurs (which we’ll cover in a later section).

3. Damage

Damage refers to anything that causes the inventory to become unsellable. This includes broken packaging, cracks, tears, water damage, product expiration, and more.

4. Management errors

Inventory management errors such as miscounting, using the wrong units of measurement, administrative errors, or any other type of human accounting error can lead to inventory shrinkage. This kind of error is still possible even when automation is used for inventory management, so make sure that you leverage best-in-class inventory management software and tools to avoid it.

7 ways to prevent inventory shrinkage

The good news is there are a lot of ways to prevent inventory shrinkage. Any combination of these methods may work depending on whether you are warehousing products or have your own storefront.

1. Install inventory tracking

Tracking items isn’t hard and can help you see whether a piece of inventory disappeared out of the warehouse or the retail floor. For example, fashion brands in the retail industry have had great success with the ink blot tag systems. Grocers are even able to lock their carts if they leave the vicinity of their parking lot.

“One of our main priorities was finding a reliable partner that could store all of our inventory and provide tools that would help us manage it. We rely heavily on ShipBob for inventory tracking and forecasting and that’s been a key part of our partnership. Our area of expertise is not logistics or inventory management, so we lean on ShipBob a lot for that. We’ve learned so much about this industry since working with ShipBob, as they are true supply chain experts, which has been good for everyone on our team.

When thinking about fulfillment, there’s such a focus on the packing and shipping aspect that the inventory management piece can often go unnoticed. But ShipBob’s ability to help us track and reconcile inventory is really great.”

Callie Tivnan, E-commerce Manager, and Christina Williams, Customer Success Manager at Barefaced

2. Count inventory often

When you count your inventory regularly, you’ll have more opportunities to notice discrepancies – and you’ll usually be able to catch those discrepancies more quickly. You can do this in a cyclical manner to minimize the amount of time it takes, or use technology that can keep inventory counts updated in real-time (rather than in Excel, which is static and not synced to anything).

3. Surprise audits

If employees are stealing from you and they know when audits are coming, it gives them time to prepare. With a surprise inventory audit, you can more quickly find anomalies in your inventory counts without prompting staff.

4. Heightened security measures

If you run a single brick-and-mortar store, it may be useful to install cameras and security systems in your shop or your inventory storage system. You can also make use of clear garbage bags to ensure no one is pretending something is trash but actually putting inventory in a bag that they take for themselves.

5. Split responsibilities

If a single employee has access to recording and processing receipts, they could be tempted to falsify the reports. You can counteract this by letting different employees handle recording and processing receipts, which also helps bolster quality assurance.

6. Educate employees

Employees may not be aware of how inventory shrinkage affects them. Use this as an opportunity to let them know how shrinkage affects them directly and indirectly, including how it decreases promotions, paychecks, employee profit shares, and more.

7. Work with an expert fulfillment partner

Third-party logistics partners, or 3PL providers, are professional fulfillment companies that help ecommerce businesses store inventory and fulfill orders. They take precautions to keep your inventory safe and secure while allowing merchants to outsource fulfillment, which is often costly and unproductive to manage in-house.

The best fulfillment partners will also provide transparent reporting and technology to help you control stock levels to prevent inventory shrinkage.

“We have over 5,000 SKUs, but that hasn’t been a problem for us in working with ShipBob. Their dashboard gives us visibility to inventory management, which has been excellent. ShipBob’s inventory counts are very accurate to what’s on-hand, and we can always see what we have available there. We also have an integration between our ERP, NetSuite, and ShipBob, so inventory data is always being fed back into NetSuite for us to view inventory counts there.”

Charlotte Katona, President of Makesy

Shrink shrinkage, scale profits: Discover ShipBob’s services

As an expert supply chain partner, ShipBob does more than just store your inventory; we’ll help your brand (and thousands more) manage inventory effectively so you can maximize your ROI, meet customer demand, and ultimately run a smoother, more profitable business.

Here are just some of the ways that ShipBob helps brands like yours avoid inventory shrinkage while optimizing inventory management.

Real-time insight into inventory levels to minimize loss

ShipBob’s platform features key inventory management capabilities, including access to real-time inventory levels across all your sales channels and locations. With this degree of visibility, you can track how inventory is moving across your supply chain, if and where it’s going missing, and nip inventory shrinkage in the bud.

ShipBob also leverages barcode scanning at every stage of inventory flow, so inventory counts are automatically updated (as opposed to manually). This reduces human errors, saves you time, and enables you to maintain granular inventory visibility even as you scale.

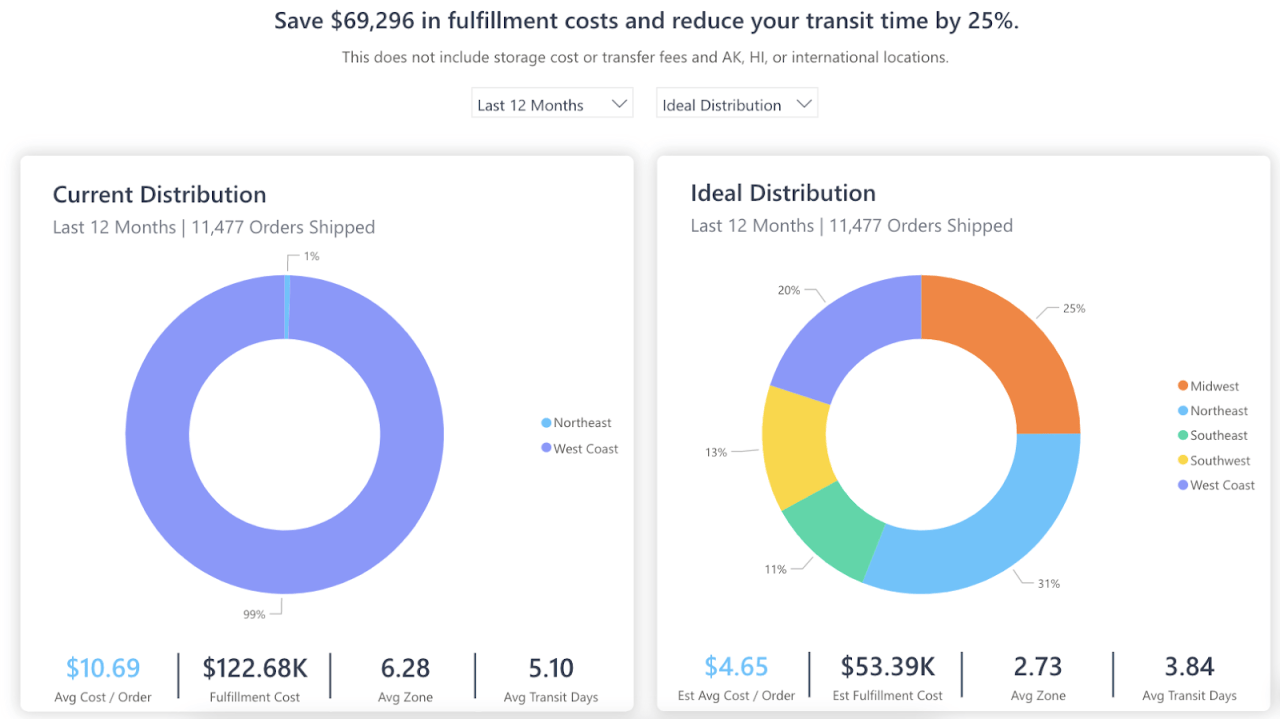

Strategic inventory distribution for faster and safer fulfillment

The more you move and transfer inventory internally during the fulfillment process, the more chances there are for inventory to be lost in the shuffle, damaged, or stolen. As a result, you want to streamline your inventory allocation and distribution process as much as possible – and ShipBob can help.

ShipBob’s Inventory Placement Program (IPP) is designed to take inventory balancing, allocation, and distribution off your plate and into the hands of trusted experts. It starts with our proprietary algorithm, which leverages your actual order data to calculate the inventory split across our fulfillment network that will best enable you to meet customer demand while minimizing shipping costs and times.

From there, all you have to do is send your inbound inventory to a single ShipBob receiving hub, and ShipBob will take care of physically distributing your inventory to regional facilities for you. This simple process not only reduces opportunities for inventory shrinkage in transit, but can also save you time and money.

“Right after we partnered with ShipBob, we joined their Inventory Placement Program, which streamlines inventory distribution across the US, taking multi-location inbound shipments, inventory allocation, and rebalancing off merchants’ plates. Since launching in the program, we’ve been able to allocate our inventory across 4 of ShipBob’s fulfillment centers in the United States, which cut our shipping times by a third – from 5.2 days down to about 3.6 days.

Not only has transit time dropped, but at the same time we reduced fulfillment costs by over $2 per order compared with our old 3PL. This combination has been key to profitable growth this year.

And the cost to split inventory this way? It’s a no-brainer. It costs less for us to deliver all inventory to one location that’s close to our manufacturer partners in NJ, and let ShipBob take care of splitting the inventory between the four different warehouses than it would for us to ship and handle logistics ourselves.”

Matt Crane, Co-Founder and Chief Science Officer at Semaine Health

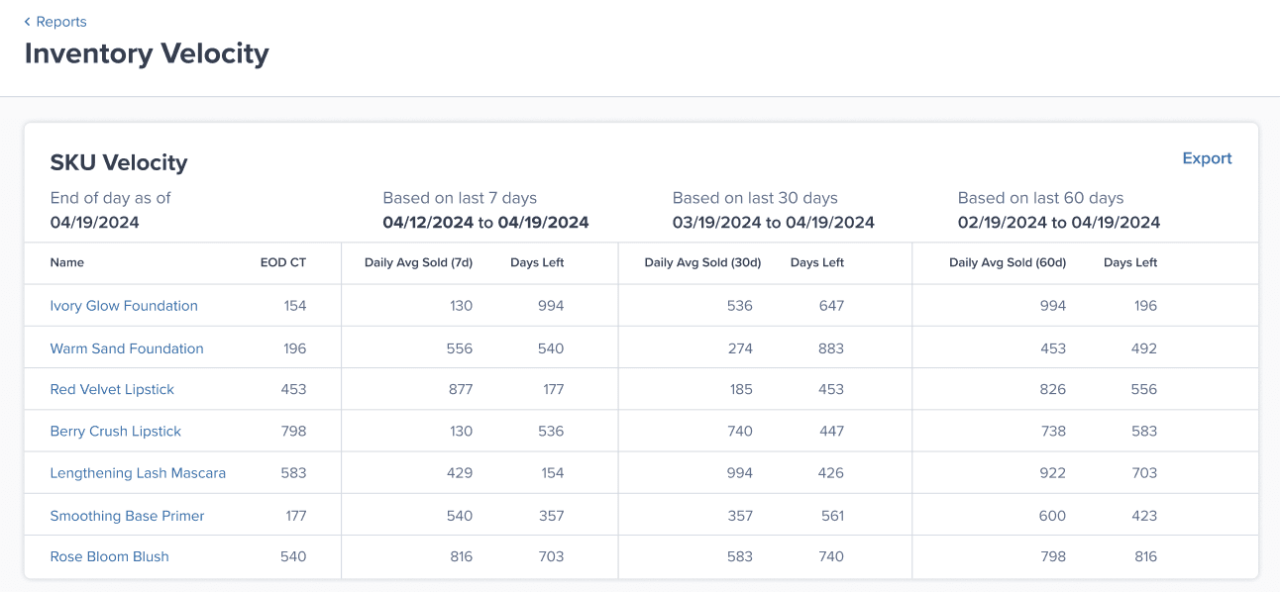

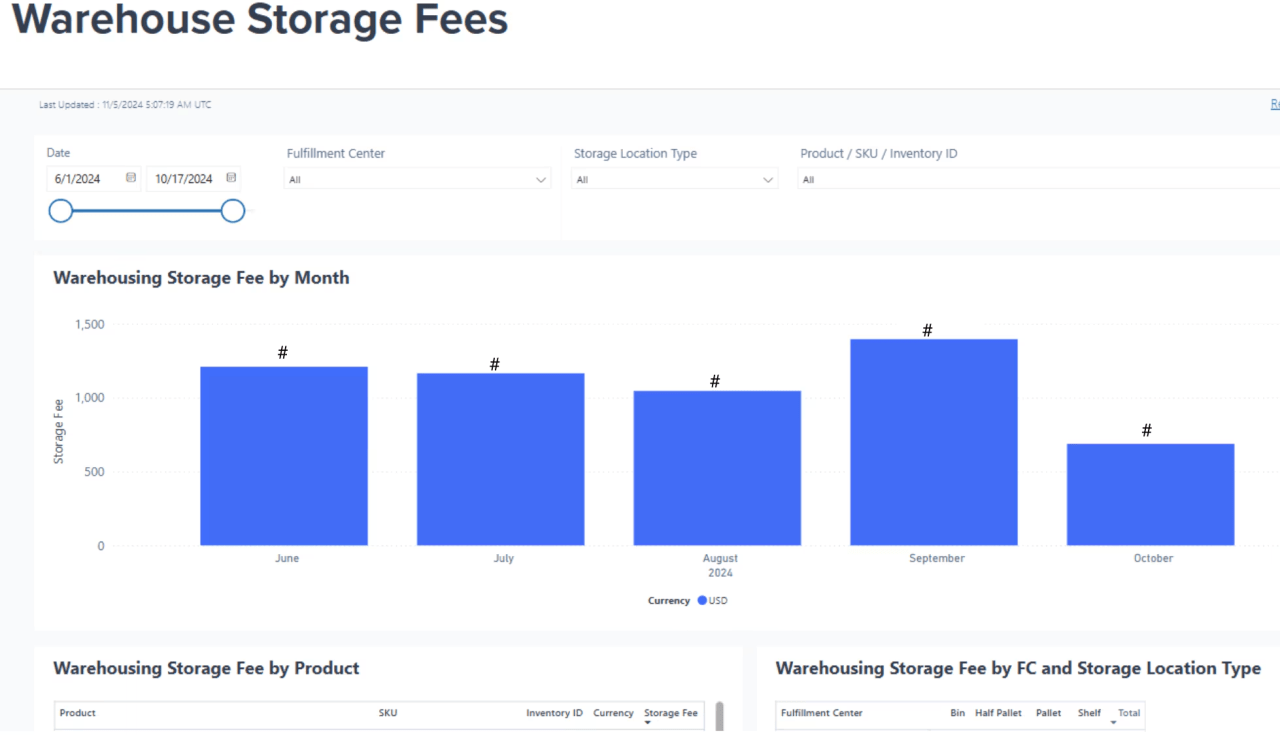

Built-in analytics to spot and stop shrinkage trends

ShipBob’s analytics dashboard delivers the data and insights you need to manage your inventory effectively, including identifying and addressing inventory shrinkage. Along with real-time inventory levels at every stage of the fulfillment process, ShipBob’s reporting covers:

- Average daily velocity per SKU

- Your best- and worst-performing SKUs

- Estimated inventory days on-hand

- Products and quantities out of stock

- Current inventory distribution

- Warehousing storage costs by product and location

With this data, you can improve demand and inventory forecasting, monitor inventory movement across the fulfillment process, reorder inventory on time, and make more strategic inventory decisions and adjustments.

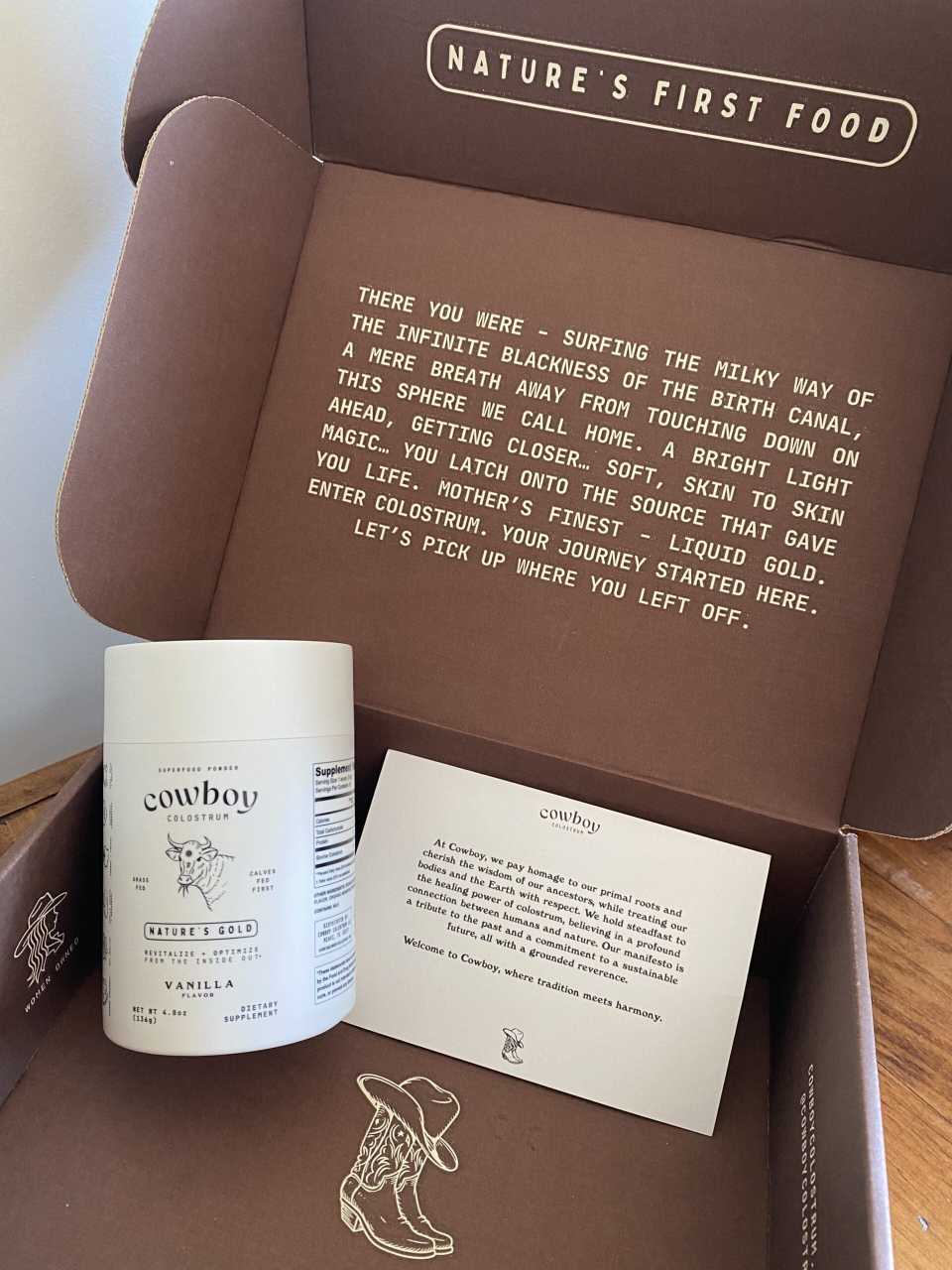

Custom packaging and careful handling for brand integrity

For brands worried about inventory getting lost or damaged in the packing processes, ShipBob’s team of fulfillment experts follow a packing flow that includes checks and balances at every stage to minimize human errors and ensure product integrity. We can also accommodate kitting requests and custom packaging – including branded boxes and polymailers – to help protect products in transit and deliver a memorable unboxing experience for your brand.

For more information on how ShipBob can help your brand minimize inventory shrinkage while optimizing fulfillment, click the button below to get in touch.

Inventory shrinkage FAQs

Here are answers to some of the most common questions about inventory shrinkage.

What is considered inventory shrinkage?

Whenever a SKU’s inventory levels are less than they were recorded to be for accounting purposes, there has been inventory shrinkage.

Is inventory shrinkage an expense?

Yes, inventory shrinkage is considered an expense. Every piece of inventory that’s missing is essentially lost sales and money for your business, and should be considered an expense.

What is an inventory shrinkage example in retail?

Say a retail store records $10,000 in inventory value at the beginning of the year. Later, a basement flood damages $2,000 of inventory (making it unsellable) and an employee steals another $1,000 of inventory. This $3,000 of inventory would be considered inventory shrinkage, as it is lost to the business, and the business cannot sell it or recoup their initial investment in that inventory.