Table of Contents

** Minutes

What is supply chain management?

How does SCM work? 5 key stages

Types & examples of supply chain management

The benefits of stellar supply chain management

Products go through quite a journey before they reach your customers. They are manufactured, reviewed for quality, stored temporarily, and shipped (often several times) before they actually reach the end consumer.

Each step is part of the retail supply chain. Proper supply chain management (SCM) is crucial to optimizing inbound and outbound logistics processes as well as growing your business.

Even one broken link in the ecommerce supply chain can lead to a ripple effect that ultimately leads to harmed margins, lost revenue, slow supply chain velocity, and a drop in customer satisfaction.

To help your brand avoid those effects, we’ll cover how supply chain management works for ecommerce businesses, what the global supply chain looks like, and best practices for SCM.

What is supply chain management?

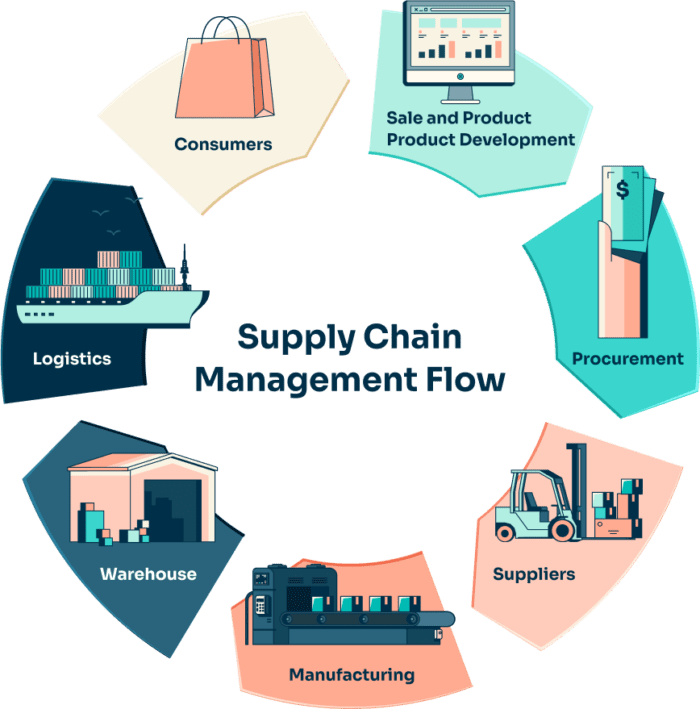

Supply chain management (or SCM) involves overseeing the movement of all the materials, finished goods, and processes that come together to get products to customers. This includes every supply chain function, from production to last-mile delivery.

Source: Recurrency

For example, say an ecommerce business makes and sells scented candles. This business’s supply chain consists of sourcing raw materials like wax, wicks, and glass containers from suppliers, creating the final products, fulfilling orders, and shipping orders from their warehouse to a customer’s doorstep via carrier partners.

In this example, the candle business’s supply chain management might include:

- Determining how many of which candle scents to create

- Placing an order for raw materials from the supplier

- Arranging and timing transportation of raw materials and finished goods

- Auditing inventory and monitoring inventory levels over time

- Partnering with a 3PL for order fulfillment

Why supply chain management is so important

Because supply chains are multi-phase endeavors, they require a lot of coordination to run efficiently. SCM is that coordination – that is, all the management activities that keep a supply chain operating smoothly.

It can take a lot of effort, but supply chain management is a worthwhile endeavor. By constantly monitoring and optimizing the flow of goods through your supply chain, you can:

- Prevent disruptions and bottlenecks: Managing your supply chain helps you time functions like procurement, receiving, fulfillment, and shipping strategically, so you avoid delays and confusion.

- Save money: When your supply chain runs like a well-oiled machine, you waste less money on inefficiencies, correcting mistakes, and opportunity cost.

- Shorten lead times: In a coordinated supply chain, goods move quickly and efficiently through workflows and stages (rather than getting stuck in limbo). This minimizes lead times, and helps end customers get their orders faster.

- Stay stocked: Effective supply chain management ensures that your brand has enough inventory to meet demand at any given moment and prevents costly shortages, stockouts, and backorders.

- Deliver a seamless customer experience: With all supply chain stages working together, it’s easier to create accurate, timely, and polished deliveries across all your sales channels.

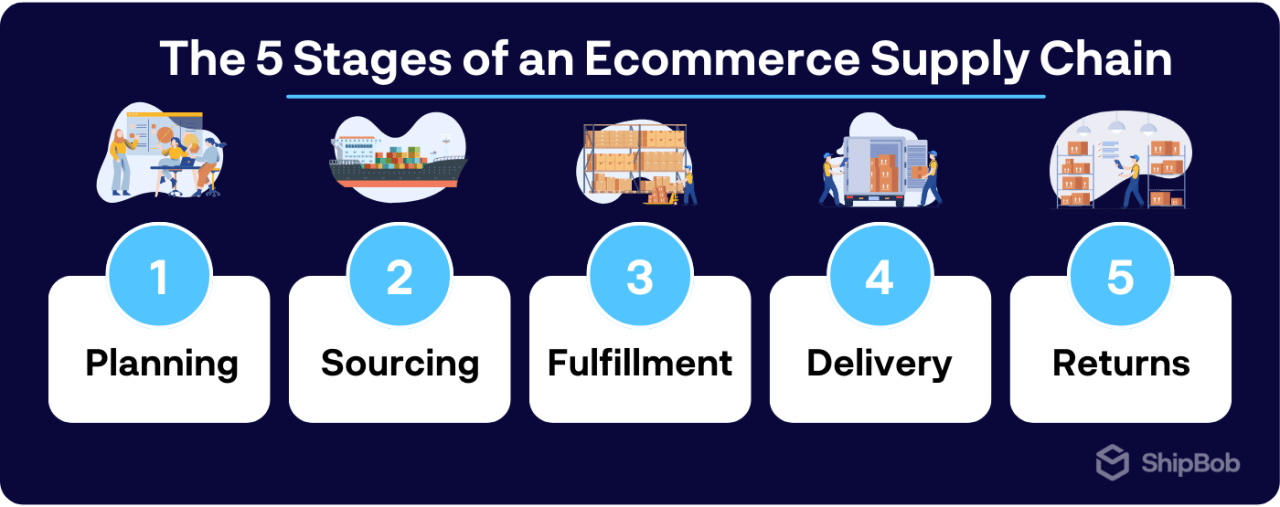

How does SCM work? 5 key stages

Ecommerce businesses have a different supply chain compared to brick-and-mortar retailers. Instead of having products shipped to a retail location, products are stored in an ecommerce warehouse and shipped directly to consumers. Here’s an overview of what the ecommerce supply chain looks like.

1. Planning

Good supply chain management begins with accurate demand forecasting. Demand planning allows you to anticipate changes in volume and reorder stock at the right time so that you always have just the right amount of inventory.

If you don’t correctly estimate how much demand there will be for each SKU, you may stock out (leading to backorders and dissatisfied customers) or end up with too much stock (inflating your holding costs).

To get the best demand forecasts possible, study historical sales data for past patterns that may repeat themselves. You should also factor in trends, seasonality, and geographical values or needs, as these can also affect demand.

Implementing an inventory management system (or IMS) can make it easier to track and analyze this data over time.

2. Sourcing and manufacturing

Next, your business must manage procurement – in other words, how and when you obtain the products you’ll sell.

The fundamentals of strategic sourcing are finding a supplier and arranging for inventory transportation.

Find a supplier

The first stakeholder in the supply chain (other than your business) is the manufacturer. Regardless of what types of products you sell, you’ll need to find a supplier that can manufacture your product in a safe, cost-efficient, and timely manner.

Here are some questions to ask when evaluating potential suppliers:

- Where are the raw materials coming from?

- If your manufacturer is overseas, have you ever evaluated the shipping savings of a closer-to-home supplier?

- Can your goods be made closer to home?

- Have you looked at diversifying your suppliers to have other sites as backups for supply chain risk management and supply chain resilience in the event that a factory shuts down?

- Can you cut costs and production lead times?

- Does your supplier know when products need to be reordered?

- Can your manufacturer further package or build your products to reduce the need for kitting and assembly in the fulfillment center?

Having risk management built into your supply chain at times like the COVID-19 pandemic are more important than ever.

Arrange for inventory transportation

Once you’ve selected your manufacturers and/or suppliers, you must then coordinate with them on how your product(s) or raw materials will be transported. If you have multiple warehouses or distribution centers, you need to ensure that the right amount of inventory reaches each specific warehouse and the proper documentation is included with the freight shipments.

Demand planning allows you to anticipate changes in volume and ensure orders are placed at the right time so that you never run out of inventory and also don’t have money tied up in excess inventory. An inventory management system can help manage this.

3. Fulfillment

After inventory is transported from the supplier or manufacturer and arrives at your ecommerce brand’s warehouse or fulfillment center, the next supply chain stage is fulfillment.

Fulfillment is a multi-phase process that consists of receiving and storing inventory, processing orders, picking items, and packing them for shipping.

Receive and store inventory

Once inventory is received at a fulfillment center, it must be properly stored. Each SKU needs its own unique storage spot for accurate and fast retrieval (e.g., a red shirt that is available in S, M, L, XL, and XXL will require five separate storage locations).

Process orders

Inventory will remain in storage until an order comes through from one of your business’s sales channels. Whether it’s placed on your ecommerce website, a social channel likeTikTok Shop, or a dropshipping order through a retail partner like Target or Macy’s, your order management system must confirm the order and route it to a warehouse or fulfillment center.

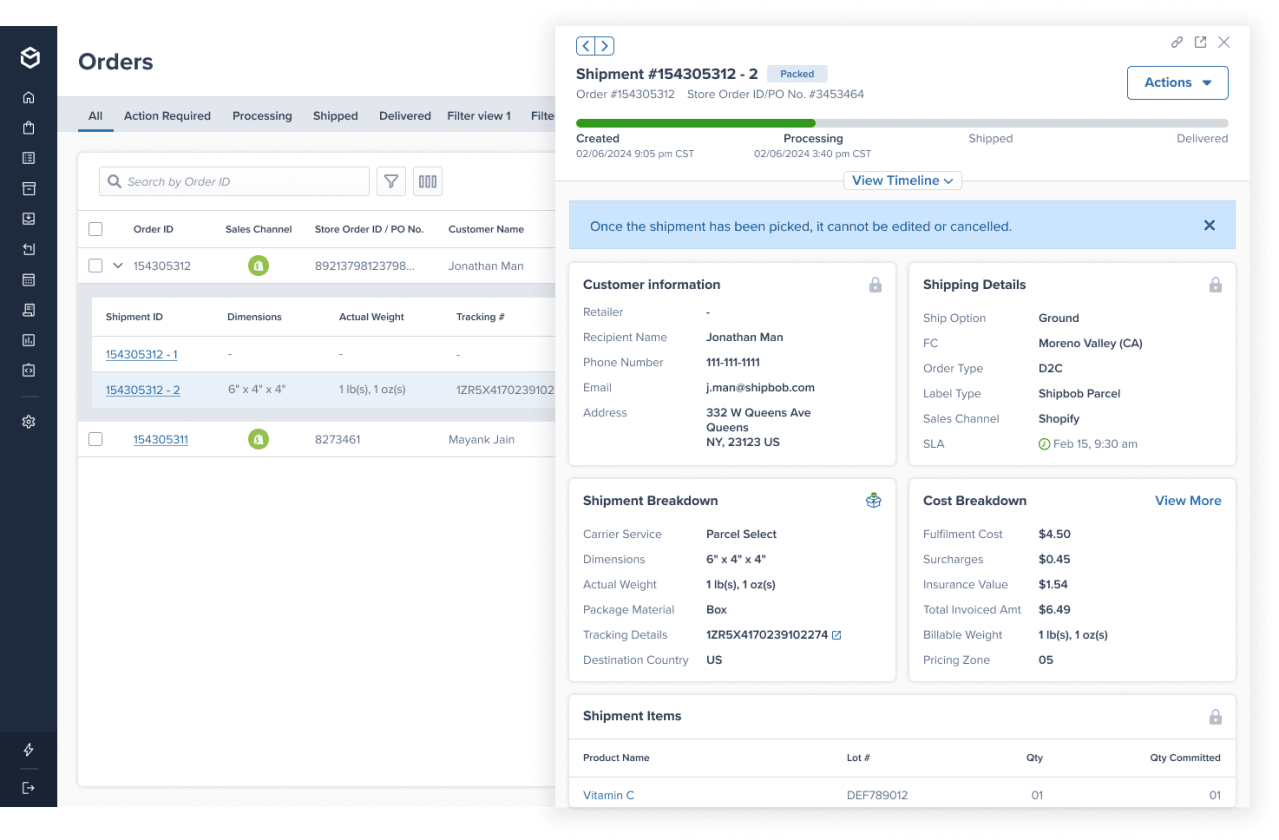

Some 3PLs, like ShipBob, integrate directly with a business’s ecommerce store to automatically process orders. They may even automatically assign those orders to be fulfilled in the fulfillment center closest to the order’s final destination to minimize shipping times and costs.

Pick and pack orders

When inventory arrives at the warehouse or fulfillment center where it will be stored, the first step in fulfillment is to receive the inventory. In receiving, warehouse associates open the pallets or boxes of inventory, inspect their contents for damage, and count every item to ensure the correct products were delivered in the correct quantity. If your warehouse uses barcoding to track inventory levels in real-time, warehouse associates will scan each item’s barcode to enter it into the system and log its arrival.

Once an order is confirmed, the items in that order must be retrieved from storage. This process, called picking, is usually done by hand but optimized for accuracy and efficiency using barcode scanners, pick list generation, and other automations.

Picked items are then transferred to packing stations, where they are placed inside a box or poly mailer. Businesses may choose to customize their packaging to delight customers or advertise their brand (though this can add complications and slow operations if implemented incorrectly).

4. Delivery

Packed orders must then be delivered to end customers. To do this, you must select your carriers, prepare orders for shipping, and hand packages off for last-mile delivery.

Selecting a carrier

Merchants will need to select a carrier partner to ship their packages. Different carriers will offer different services and rates, and some may be more reliable than others. In evaluating your options, you will need to decide what qualities are most important to your shipping strategy.

While customers expect fast shipping, it is not always affordable. With a logistics partner to strategically distribute inventory and negotiate bulk discounts on your behalf, your brand can achieve fast shipping at a good price.

Prepare orders for shipping

Next, merchants need to get their packages into the carrier’s hands. If you fulfill orders yourself, this may involve multiple trips to the post office. When you outsource fulfillment and shipping to supply chain management professionals, they will coordinate with carriers to hand off packages for you.

Last-mile delivery

From there, couriers will deliver packages to the end customer. Carriers might use multiple different modes of transportation, but ground transportation is the most common method of doorstep delivery.

Make sure you choose a carrier that you trust to keep packages in good condition, as damage in transit still reflects poorly on your brand.

5. Returns

Even after customers get their orders, they may decide to return items. Your brand should have business processes in place to manage returns, as well as to determine which items are restockable and which are not.

What links all of the parts of a supply chain?

A supply chain is made up of a lot of moving parts. There are physical goods continuously being transported, with lots of critical information that must be shared across several stakeholders.

With the combination of physical and digital counterparts, a supply chain in today’s world is a complex beast that requires a lot of attention to detail.

Transfer of physical inventory

From the manufacturer to the end consumer, there are many inventory movements across different modes of transportation including:

- Vessels moving inventory overseas

- Trucks that pick it up at the port and bring it to a fulfillment center

- Warehouse associates who receive it at the dock, count, and stow it in the fulfillment center

- Pickers and packers who retrieve inventory and pack it in the fulfillment center

- Shipping carriers who pick up daily orders at the fulfillment center, bring them to their sorting facilities, and carry out last-mile delivery

- International orders that travel via air or sea, stop at customs, and are sometimes handed off to a different carrier

For each of these movements, there needs to be a digital trail to ensure order accuracy and visibility in inventory reporting.

Transfer of information

There’s a lot of data being exchanged in a supply chain — between suppliers and buyers, sellers and customers, shipping carriers and sellers — and it must be recorded, analyzed, and shared with the proper parties in a timely manner.

From order tracking to inventory tracking, the right technology (including a centralized knowledge base) must be in place to keep information organized, clean, and accessible.

Types & examples of supply chain management

There are a few different supply chain models that businesses typically use. Each model may require different supply chain strategies.

Continuous flow

Some supply chains are built around stability. Businesses that sell the same products year after year and experience stable customer demand for them don’t see a lot of volatility in their operations. As a result, they can keep their supply chain running on a set schedule.

For example, the toilet paper brand Charmin has a strong customer base and steady demand for their product. With stability expected, the brand can continuously create and sell their product with little variation.

Continuous flow supply chains still require supply chain management. However, most SCM efforts are aimed at adjusting supply chain processes and optimizing for costs, rather than navigating surprises or market shifts.

Fast supply chain

The fast supply chain model is for businesses that sell products with short life cycles. Fashion brands, for example, must have fast supply chains, so that they can acquire, sell, and deliver clothes that fit the current trends before those trends go out of style.

Brands using the fast supply chain model will need SCM that keeps up with their sales cycles. In most cases, their SCM will be focused on forecasting demand, coordinating quick manufacturing and transportation of goods, and keeping deadstock and obsolete inventory in check.

Flexible and agile

An agile supply chain model is a must for brands that expect sporadic peaks and troughs in demand. For instance, a brand that sells Christmas tree lights will see great spikes in demand in Q4, but very little demand the rest of the year.

For these brands, supply chain management involves communicating with suppliers to ensure that the brand has enough stock to satisfy customers during periods of high demand, while auditing inventory to avoid overstocking in leaner periods.

The benefits of stellar supply chain management

Supply chain planning and management is what keeps a business moving. Therefore, if it’s slow or not optimized, you can’t grow efficiently. Ecommerce businesses of all sizes have a lot of unseen opportunities to improve their supply chain.

Whether it’s diversifying manufacturers and working with local suppliers, changing how inventory is stored in warehouses, or even outsourcing fulfillment to the right third-party logistics (3PL) provider, there are plenty of ways to improve your supply chain to save money and keep customer satisfaction high.

Having the right amount of product at the right time

If you don’t have enough safety stock, you run the risk of stockouts and backorders, causing your customers to wait longer for their orders. With too much inventory, you’ll have to pay high warehousing fees, which eats up your capital.

Proper supply chain management ensures you can anticipate and forecast demand for products and always have enough on hand.

Minimizing lag time between parts of the supply chain

By analyzing and optimizing your supply chain, you can minimize lag time and make the chain more efficient.

- Are your products taking too long to be manufactured? Negotiate better terms or find another supplier.

- Are your transit times slow and average shipping zones high? Analyze your warehouse locations and determine fulfillment center location(s) that are closer to your end customers.

- Are you constantly out of stock for popular products? Up production, invest in inventory forecasting, set more frequent reorder points, and increase your reorder quantity.

By examining every aspect of your supply chain, you can find improvement opportunities and implement changes as needed.

Reducing fulfillment costs

Order fulfillment can be costly for your business if it’s not implemented strategically. Inefficient inventory storage, poor geographic locations, high shipping costs, and unoptimized labor and operations management can add up over time and kill your margins.

With good supply chain management, ecommerce businesses can not only minimize fulfillment costs, but actively transform fulfillment from a cost center to a revenue driver and competitive advantage.

Leveraging technology for better visibility

Efficient SCM almost always requires up-to-date software and tools. These tools not only provide increased visibility throughout different supply chain stages for a more comprehensive view, but also reveal new opportunities for improvement in particular areas.

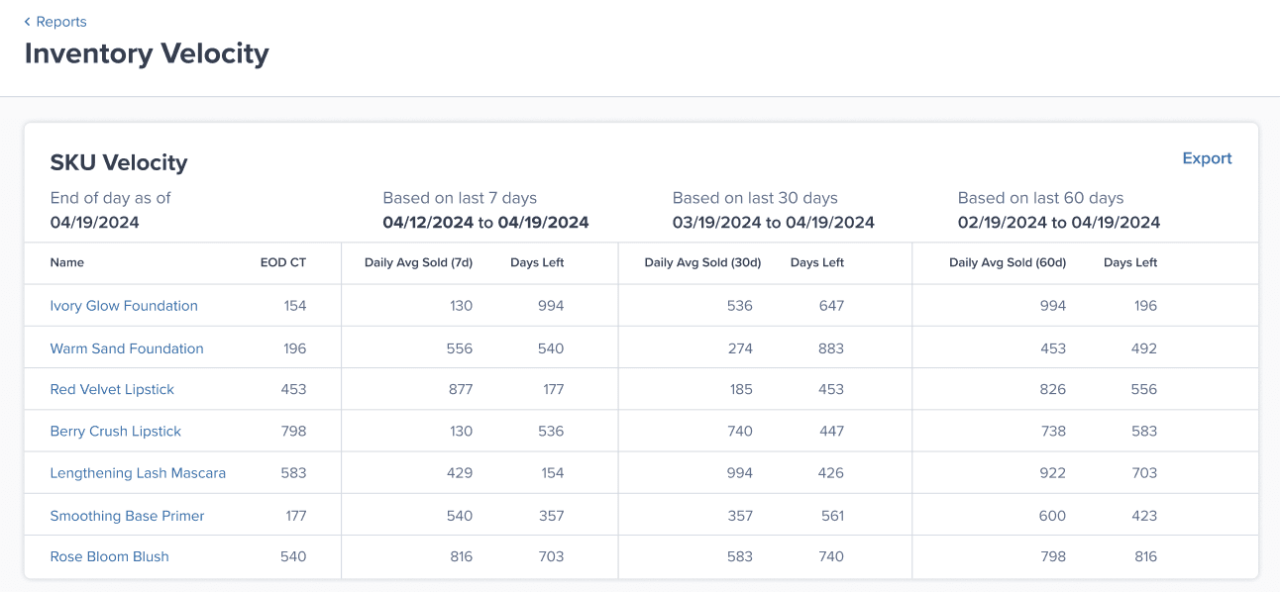

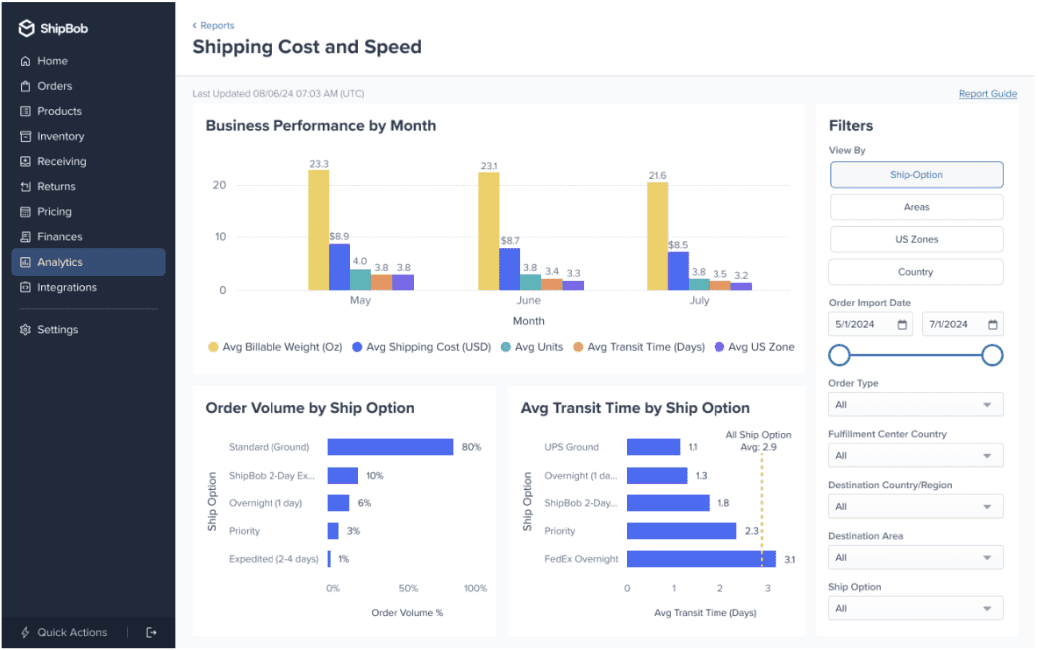

For example, ShipBob’s merchant dashboard combines the best of inventory, order, and warehouse management to deliver real-time analytics on every supply chain phase.

ShipBob customers can track inventory levels and KPIs, access historical order data, and monitor fulfillment performance to pinpoint optimization areas, and improve their supply chain management.

Improving environmental sustainability

Through good supply chain management, a business may minimize its environmental impact. By making eco-conscious choices with regards to suppliers, manufacturers, transportation, and inventory management, your supply chain can run efficiently without deepening its carbon footprint.

For instance, businesses can partner with local suppliers to avoid the heavy carbon emissions of ocean or air freight. Similarly, optimizing transit routes to minimize the number of trips inventory makes also reduces carbon emissions.

Merchants can also distribute their inventory to be closer to customers (shortening transit distances) and manage inventory levels so that less deadstock ends up in landfills.

Streamlining logistics across the board

When your supply chain is properly managed, your logistics become much easier. This is especially true when your brand partners with a supply chain and fulfillment platform like ShipBob.

The right partner will use their expertise to optimize your supply chain for speed, efficiency, and cost, and help you streamline logistics across inventory management, fulfillment, and shipping.

This also gives you time back to focus on other strategic priorities, like marketing or product development.

How ShipBob simplifies supply chain management

Ecommerce companies that don’t want to oversee warehouse management themselves can simplify – and improve – their supply chain strategy by outsourcing key supply chain functions to ShipBob.

Fulfilling your own orders is time-consuming and costly, and involves lots of labor, training, certifications, resources, safety measures, and other costs that make it unappealing to many.

On the flip side, ShipBob’s team are experts in supply chain management, know how to optimize operations, and will keep you up-to-date on the latest supply chain trends and technology.

ShipBob fulfills orders for thousands of ecommerce brands across their global network of fulfillment centers and gives brands time back to focus on marketing, product development, and more.

Here’s how ShipBob can improve your supply chain management.

Better inventory management

The best supply chain partners give you the information you need to manage inventory without having to store products yourself. ShipBob’s dashboard tracks inventory levels for all products in one place and in real-time, and you can set automatic reorder notifications to make sure you time replenishment correctly and avoid stockouts.

Distributed inventory

ShipBob has dozens of fulfillment centers across the US (as well as locations in the UK, Europe, Canada, and Australia) to help get your products to customers quickly and affordably.

By shipping orders from the warehouse closest to each end customer, you can reduce your fulfillment costs, shipping costs, and lead times – all of which can boost customer satisfaction and repeat purchase rates.

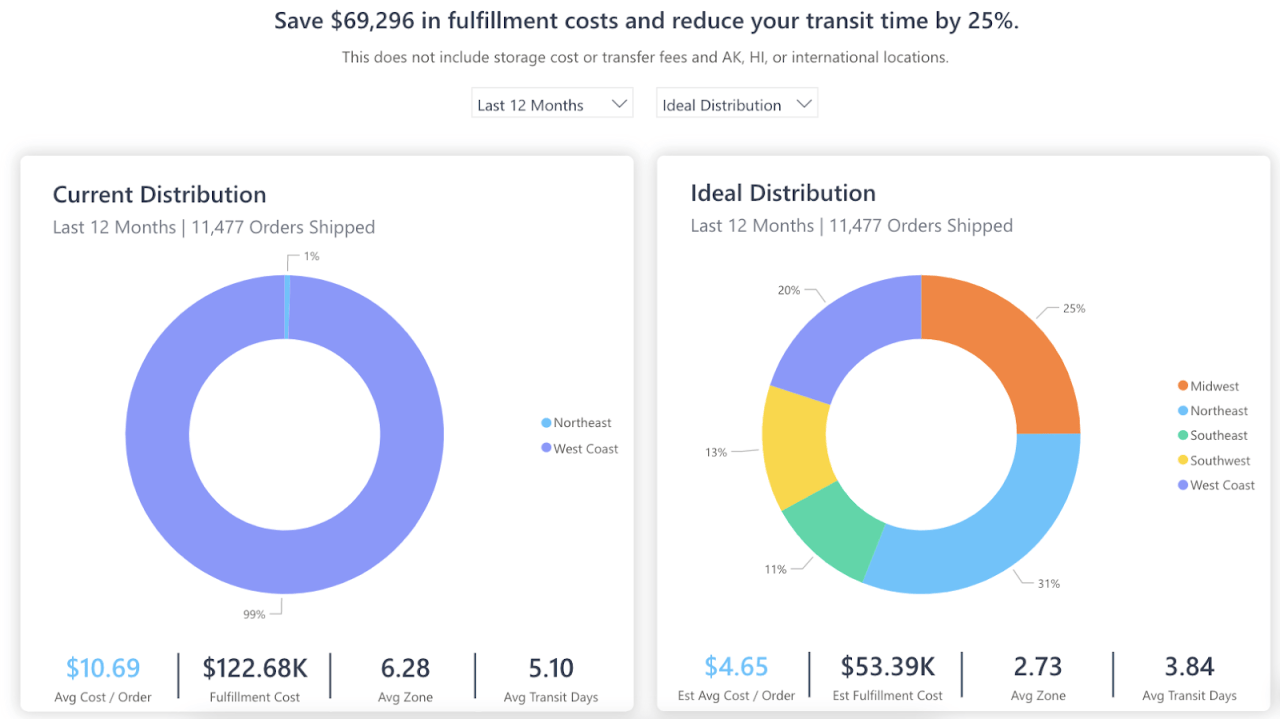

Using ShipBob’s Ideal Inventory Distribution tool, merchants can even calculate the most strategic allocation of inventory throughout ShipBob’s fulfillment network to speed up shipping while lowering average shipping cost. Through ShipBob’s Inventory Placement Program, ShipBob will even handle physically distributing your inventory to regional fulfillment centers for you.

2-day shipping

2-day shipping is a great conversion tool, and drives a lot of revenue.

With ShipBob, you can ship 2-day across the entire contiguous US affordably (even from a single fulfillment center), so your brand can compete with retail giants without having to spend an exorbitant amount of money.

“ShipBob ships our orders out super fast – faster than we had been shipping our own orders. Our stated lead time for our business had always been between 3-7 business days, and with ShipBob, most of our orders are shipped the same day or within 24 hours. It’s cut our lead times by two-thirds at least.”

Charlotte Katona, President of Makesy

Order management

With real-time visibility into your orders from the ShipBob dashboard and automated order processing, you can keep customers up-to-date and also easily access order management and supply chain performance metrics.

“ShipBob’s analytics are a huge bonus for a merchant looking to partner with a single 3PL that has a built-in order management tool. I was so stoked about being able to see the optimized layout of where you should be distributing your inventory is great. Having inventory and warehouse management capabilities built into your 3PL is such a value-add, especially for smaller companies.”

Juliana Brasil, Director of Operations at Food Huggers

Conclusion

Your ecommerce supply chain can affect how your business grows. With a properly managed supply chain, you can scale your business without having to constantly worry about manufacturing, inventory levels, warehouse issues, shipping, and more.

There are unseen profits to be gained from fixing even a few minor inefficiencies in your supply chain to make your supply chain leaner. You may be surprised at the amount of waste that’s in your own supply chain.

If you want to learn more about how your ecommerce business can optimize your supply chain through ShipBob, request a retail fulfillment quote below and our supply chain professionals will be in touch shortly.

Supply chain management FAQs

Here are answers to common questions about supply chain management.

What are the basic steps of supply chain management?

Supply chain management involves:

- Forecasting demand

- Selecting partners

- Sourcing raw materials and products from suppliers or manufacturers

- Coordinating freight inventory shipments

- Receiving and storing inventory

- Fulfilling orders

- Arranging last-mile shipping and delivery

What are simple examples of SCM?

If an ecommerce business knows demand increases during the holidays, good supply chain management would be forecasting inventory accurately, ordering enough inventory to meet demand from the supplier, and arranging for that inventory to be sent to the business’s warehouses before the holidays begin.

If an ecommerce brand wants to introduce new products in its line, good supply chain management would mean sourcing raw materials, evaluating suppliers and manufacturers, placing a purchase order, and coordinating transport for the materials.

If an ecommerce brand experiences an unexpected spike in order volume, good supply chain management means ensuring picking and packing teams are staffed up, ordering more packaging materials, replenishing SKUs that hit their reorder threshold, and communicating with last-mile carriers.

What is the difference between supply chain management and logistics management?

The terms supply chain management and logistics management are often used interchangeably. Both refer to overseeing the efficient flow of information and inventory through the supply chain.

Who is responsible for managing the supply chain?

Ecommerce businesses may have a supply chain manager, who is responsible for overseeing and coordinating all supply chain functions.

Alternatively, businesses can outsource elements of supply chain management to a 3PL or logistics partner, which can leverage their expertise to optimize your supply chain.

Can ShipBob help me with SCM?

As a tech-enabled global logistics partner, ShipBob can help DTC and B2B ecommerce businesses manage their supply chain.

With dozens of fulfillment centers, a full analytics dashboard, and order fulfillment capabilities, ShipBob enables merchants to streamline their supply chain operations for efficiency and cost.