Table of Contents

** Minutes

What is anticipation inventory?

Why anticipation inventory can be an ecommerce gamechanger

Watch out for these anticipation inventory risks

How to incorporate anticipation inventory the right way

One of the most challenging aspects of ecommerce inventory management is preparing for demand fluctuations. You must strike the right balance between keeping enough stock on hand to meet demand surges without overstocking your warehouse. Anticipation inventory helps alleviate this struggle by enabling ecommerce businesses to prepare for expected increases in demand.

In this guide, we’ll cover what anticipation inventory is, how it benefits ecommerce brands, and strategies for leveraging it in your own inventory management.

What is anticipation inventory?

Anticipation inventory is the extra inventory that a business secures to prepare for an expected demand surge, such as seasonal shifts or large sales.

Anticipation inventory is a vital part of demand planning, as it helps to prevent stockouts at times when those items are most highly demanded.

For instance, a clothing retailer may stock up on winter boots ahead of the winter season and swimwear ahead of the summer. This helps them effectively meet customer demand and take advantage of sales opportunities.

Anticipation inventory vs. safety stock

The terms anticipation inventory and safety stock are sometimes used interchangeably. While they both refer to extra stock, there’s a big difference in the purpose they serve.

Anticipation inventory is part of a proactive demand planning strategy, and involves acquiring extra inventory for expected demand (for example, a seasonal spike in demand). Meanwhile, safety stock refers to the buffer inventory that a business keeps on hand to address unexpected demand fluctuations (for instance, a spike in demand for a product after it suddenly goes viral on TikTok).

Anticipation inventory use cases today

As unpredictable as running an ecommerce business can be, there are lots of demand-influencing events and circumstances that brands can plan for. Here are some of the most common situations in which businesses use anticipation inventory.

- Holiday seasons: As demand tends to surge during the holidays, ecommerce businesses often secure anticipation inventory in advance to meet this increased demand as part of their regular holiday inventory preparation strategy.

- Seasonal changes: Demand for certain items tends to increase depending on the season. This could be influenced by factors such as weather conditions, seasonal activities or hobbies, and events. For instance, demand for multicolored twinkle lights will usually skyrocket in the last few months of the year, since lots of people use them in Christmas decorating (but not during any other time of year). Anticipation inventory is used to prepare for these seasonal demand changes.

- Product launches: Businesses may see increased sales for a new product just after launch. As such, they may use anticipation inventory to keep up with this demand.

- Promotions: When businesses run promotions through ads, influencers, discounts, etc., sales may increase. Anticipation inventory is used to keep up with the surge in demand resulting from a promotion.

- Expected supply chain delays: Businesses may stock up on extra inventory when they can anticipate disruptions that affect their supply chain. The anticipation inventory tides them over in case of procurement delays caused by supply chain bottlenecks.

Why anticipation inventory can be an ecommerce gamechanger

In inventory management, timing is often everything – so having extra anticipation inventory on hand when you need it can hugely benefit your business. Here are just some of the top advantages to leveraging anticipation inventory.

Prevent stockouts during high-demand periods

When you have anticipation inventory for high-demand products, you have enough unit of those items to fulfill a large number of orders for those items without running out. This helps you avoid expensive stockouts, lost sales, and canceled orders, while enabling you to effectively meet customer demand and keep shoppers satisfied even during times of demand volatility.

Optimize inventory to reduce storage costs

Anticipation inventory is based on expected future demand – so as long as your demand forecasting is correct, the extra inventory you procure will move through your supply chain quickly and be sold within a relatively short period of time. This means you won’t have capital tied up in excess inventory that sits on shelves unsold, racking up high holding costs.

Balance costs and demand

One of the biggest benefits of anticipation inventory is the ability to balance your inventory costs between low and high-demand periods. When you’re in a period of low demand but know you’re approaching a demand surge, you can plan your inventory procurement strategically to stock up on inventory while you have open space to store it, and the capital to invest in extra inventory units. This helps you prepare for high demand and relieves some of the financial strain from inventory procurement later on.

Take advantage of bulk discounts

When you know exactly what inventory you need and how much of it you need, you can sometimes negotiate a bargain by ordering inventory in bulk. If you anticipate an increase in supplier prices, buying in bulk in advance will also help you stock up on extra inventory before the price increases, which translates to cost savings.

Keep in mind, though, that bulk purchasing must be done strategically, and your demand forecasts must be accurate for this approach to work. Otherwise, you could end up with dead stock, which will negate all the cost savings that you enjoyed from bulk discounts.

Watch out for these anticipation inventory risks

Although anticipation inventory offers several benefits, it also carries a few risks. Here are a few things to watch out for when investing in anticipation inventory.

Accurate demand forecasting is non-negotiable

The whole purpose of anticipation inventory is to prepare for future demand – so if your demand forecasts are inaccurate, you could still end up with a shortage. This makes it absolutely crucial to evaluate your current demand forecasting strategy (as well as any past order data that you’re using to build your demand model) for timeliness and accuracy.

Overstocking possibilities

If your demand forecast is off, there’s also a chance that you could end up overstocking anticipation inventory. Because anticipation inventory is often highly seasonal and demand for it is timely, excess anticipation inventory usually becomes deadstock, which can be tricky and expensive to move out of your warehouse.

Higher storage costs

Anticipation inventory also adds to your inventory carrying costs. Since you’re storing extra inventory, you will see an increase in storage costs before the high-demand period starts to kick in. Be prepared to spend more money, both for the inventory purchase and for storage and handling.

How to incorporate anticipation inventory the right way

Considering the risks highlighted above, businesses need to use best practices when leveraging anticipation inventory. Here are some of key steps and tips for incorporating it into your business.

Forecast demand accurately

There’s a high risk of over- or under-stocking when it comes to anticipation inventory, so you’ll need to accurately forecast demand to get the clearest picture of your exact inventory needs.

Accurate inventory forecasts are built on lots of past order data. Look for patterns in your sales from past years or seasons to see how demand spikes over time; are there periods when you see a sudden surge in demand for specific items? Does this demand pattern continue every year? How many units do you typically sell each time? Use these insights to connect your inventory needs with customer demand.

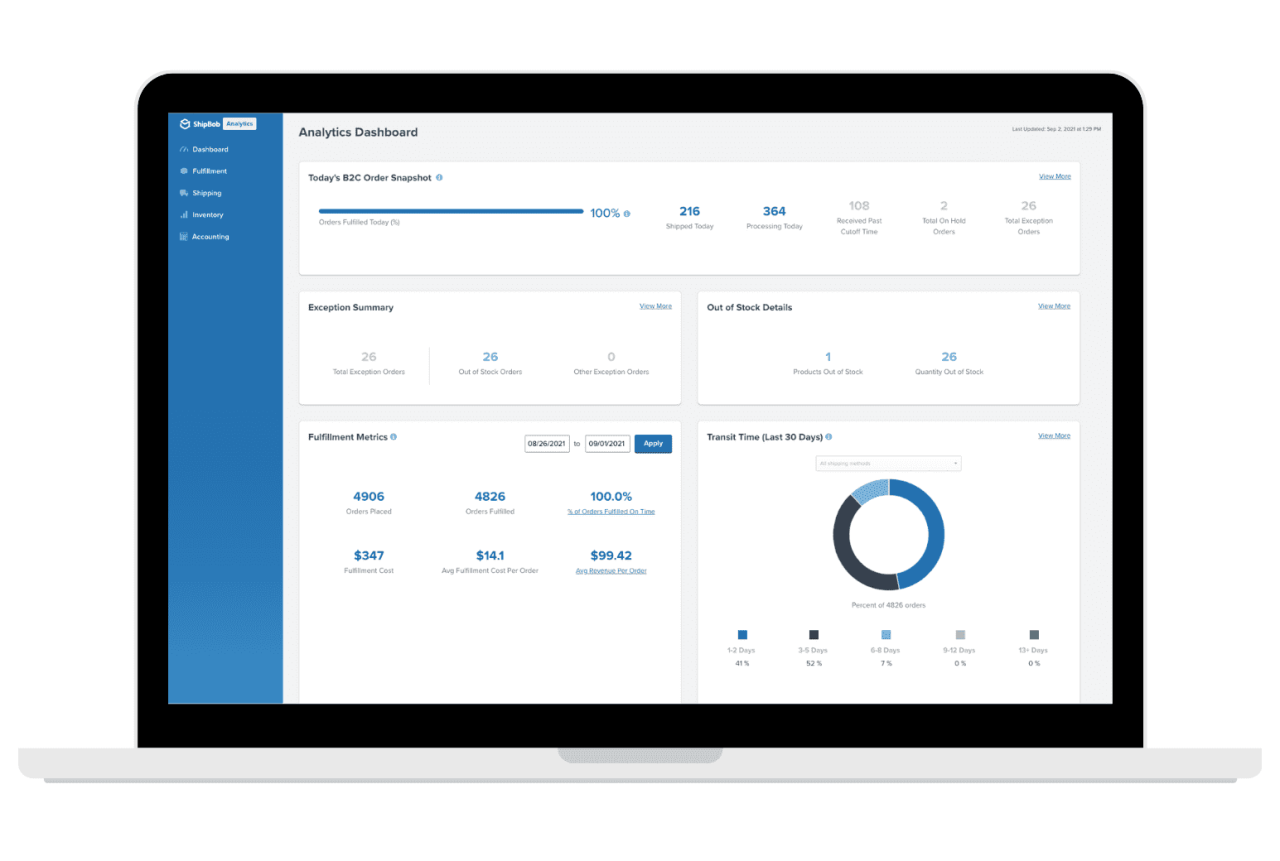

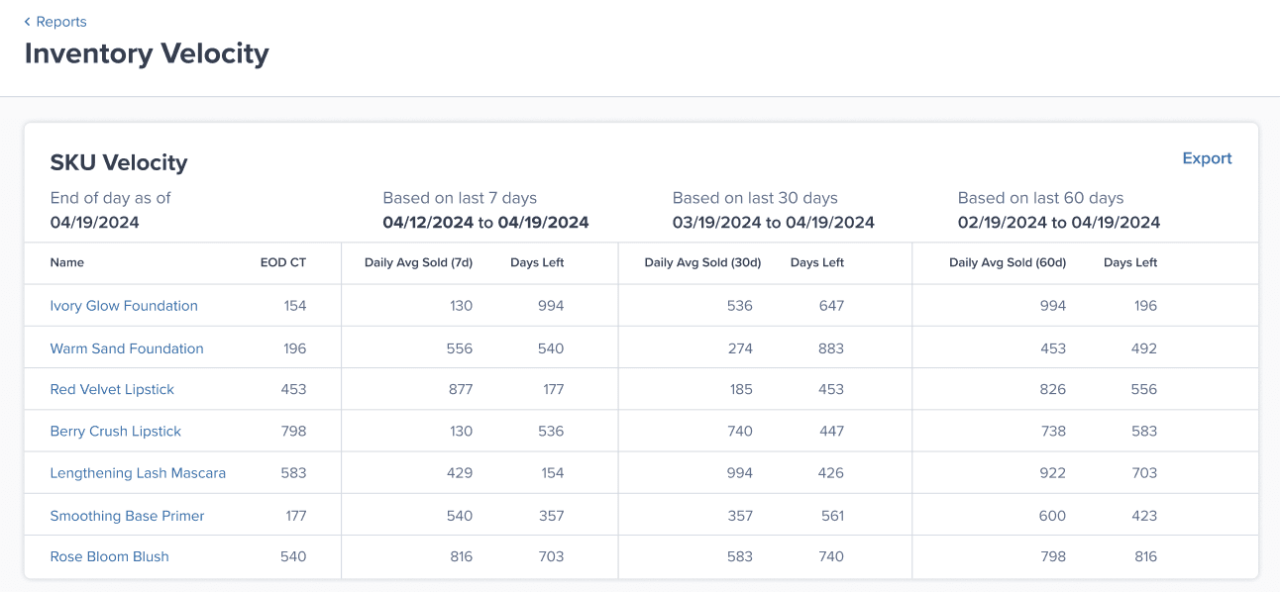

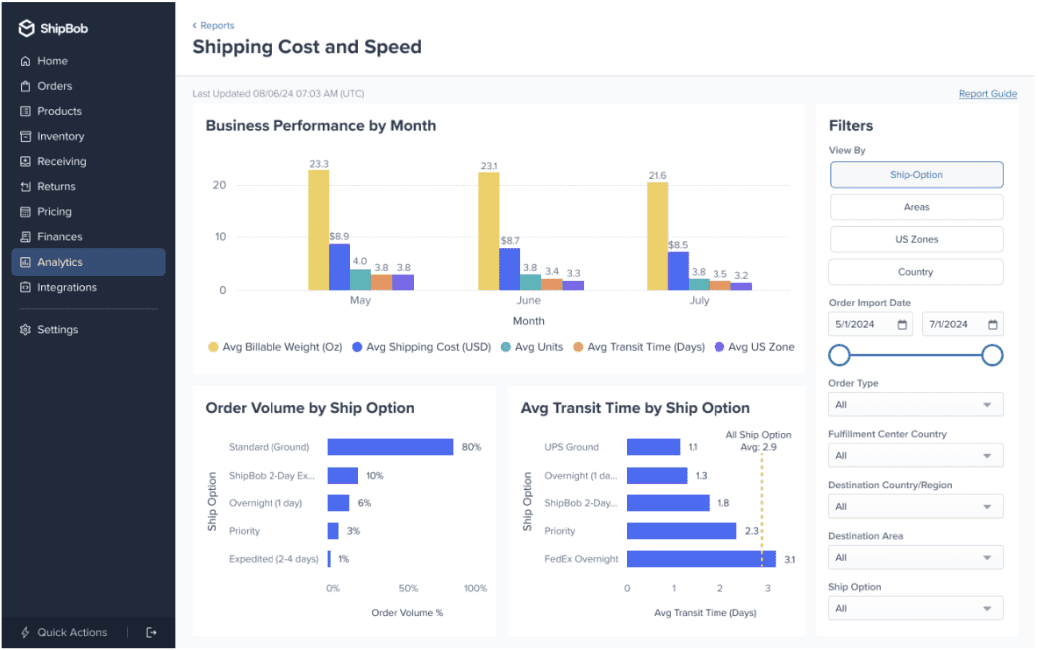

If you work with an ecommerce fulfillment partner or 3PL, they may have the data and tools to optimize the demand forecasting process. For instance, ShipBob provides merchants with a free analytics reporting tool that delivers comprehensive insights into your inventory performance and historical sales data. These insights allow you to accurately anticipate demand spikes while considering market trends.

Coordinate with suppliers

Working closely with suppliers and manufacturers will make it easier to get timely updates and tip-offs, so you can anticipate possible disruptions and price hikes and manage your supply chain accordingly. This allows you to prepare for stock replenishments ahead of high-demand periods. You can plan ahead by restocking inventory at the right time and purchasing anticipation inventory to tide you over during supply chain disruptions.

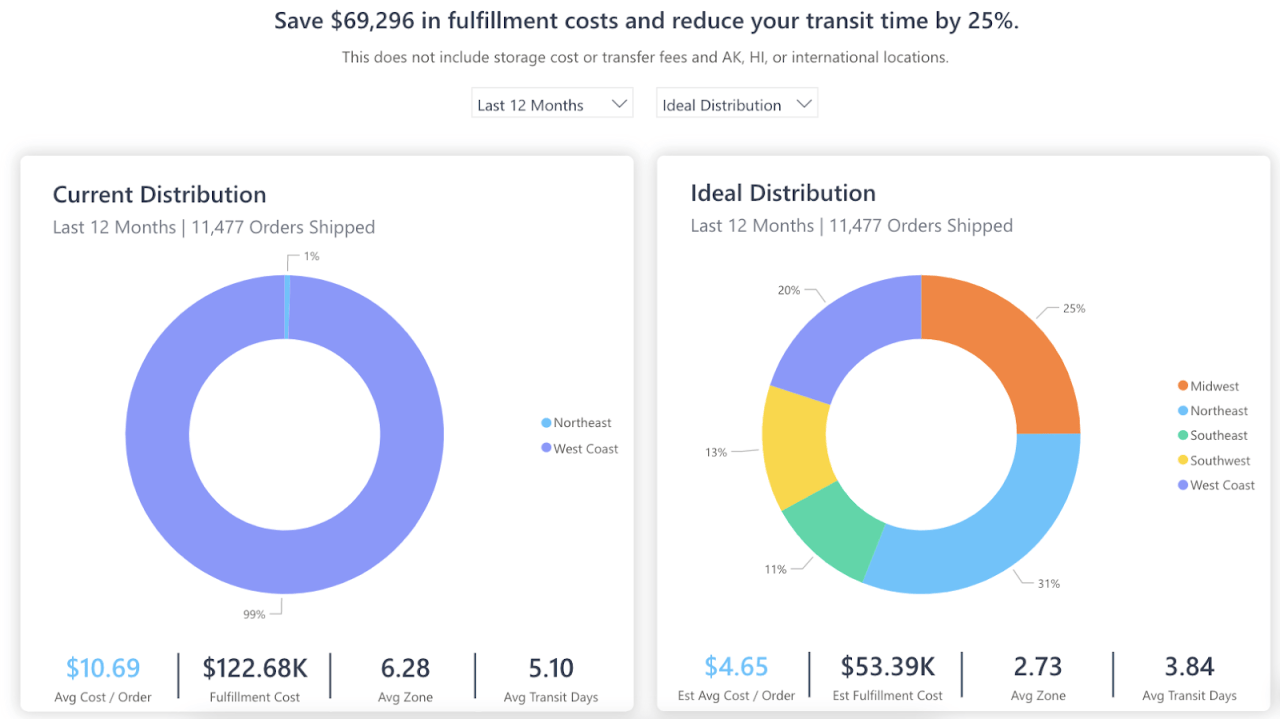

Distribute inventory across fulfillment centers

Space limitations are a major concern that businesses face when stocking up on anticipation inventory. That’s where a distributed inventory comes in handy, as it allows businesses to store their inventory across multiple fulfillment centers. Using more than one fulfillment center allows you to easily store extra inventory without taking up too much space, and lets you place it closer to the customer hubs where that inventory is most demanded.

It also allows you to ship out orders from the most convenient locations, which will significantly speed up deliveries. Since orders have to travel for shorter distances, you can also offer premium delivery experiences at a much lower cost, such as affordable 2-day shipping. All of this adds up to enhanced customer satisfaction, which could lead to repeat purchases and improved loyalty.

Optimize warehouse space around anticipation inventory

You can optimize your warehouse setup to accommodate anticipation inventory, and do so without raising costs too much.

To do this, first make use of any vertical storage space you have left to store the extra inventory, leaving space at eye-level or lower for your main inventory to keep it easy to access. Consider dedicating sections outside of your main storage area for anticipation inventory so it doesn’t take up too much space and so that the extra inventory doesn’t create clutter that could cause inefficiencies.

Monitor and adjust inventory levels

Anticipation inventory is all about maintaining balance, which can be challenging when there’s always a possibility of unexpected demand fluctuations and market changes. As such, it’s important to closely monitor your inventory levels to see where you stand and adjust your inventory strategy accordingly.

With real-time insights into your inventory, you can proactively make decisions to improve your inventory control. Whether this involves procuring more inventory based on increased demand or optimizing your storage to accommodate your additional inventory needs, real-time monitoring allows you to flex with demand and adjust your inventory levels accordingly.

How ShipBob helps optimize anticipation inventory

As an expert supply chain and omnifulfillment partner, ShipBob can help your brand handle peaks in demand seamlessly. From storing extra inventory to fulfilling thousands of orders a day, our team of experts deliver the technology, infrastructure, and best-practices your brand needs to sail through surges in demand.

Here are just some of ShipBob’s capabilities that brands can leverage as they navigate peaks in demand.

Real-time inventory management

ShipBob’s platform features built-in inventory management software that helps you track inventory levels and data in real time. This enhances your inventory visibility, so you can understand your exact inventory needs and make decisions accordingly. You get real-time inventory insights based on the most current data, which means you can quickly see when demand spikes or slows down. That way, you can adjust your inventory levels and plan your procurement accordingly.

“We have over 5,000 SKUs, but that hasn’t been a problem for us in working with ShipBob. Their dashboard gives us visibility to inventory management, which has been excellent. ShipBob’s inventory counts are very accurate to what’s on-hand, and we can always see what we have available there. We also have an integration between our ERP, NetSuite, and ShipBob, so inventory data is always being fed back into NetSuite for us to view inventory counts there.”

Charlotte Katona, President of Makesy

Powerful demand forecasting tools

Combined with real-time inventory data, ShipBob’s analytics reporting tool gives you comprehensive insights into your historical sales patterns and demand trends. These insights can be used alongside current market trends to make accurate demand forecasts and understand your anticipation inventory needs.

Distributed fulfillment network

If space limitations are a major concern, you can take advantage of ShipBob’s expansive network of fulfillment centers to store your extra inventory. This gives you much-needed space to safely store anticipation inventory until demand picks up, so you can easily adjust your inventory distribution according to demand and reallocate inventory to locations that are low on stock.

Moreover, storing inventory across different fulfillment centers helps you reduce transit times and shipping costs. You can ensure that orders are always shipped out from the nearest, most convenient locations. ShipBob even offers an Ideal Inventory Distribution tool that uses your past order data to determine the most optimal split of inventory across ShipBob’s fulfillment center network to minimize shipping times and costs.

Brands can also leverage ShipBob’s Inventory Placement Program to quickly and cost-effectively distribute your inventory to multiple regional locations. All you need to do is send your inventory to one ShipBob hub location, and our team will handle the rest.

“All we have to do is send a truckload of product to one location, and ShipBob does the rest. They push the product out with the right SKU mix by fulfillment center based on calculations for which fulfillment centers need what. It was a no-brainer to start using ShipBob’s Inventory Placement Program.

Before being a part of the Inventory Placement Program, we were shipping LTLs to each fulfillment center, so it made a lot of sense for us to take advantage of this program. Previously, our Inventory Planner was doing calculations to determine which SKUs needed to go where, but she doesn’t have to do that now.

This solution has made our jobs easier, and the pricing was competitive. There’s a level of visibility that allows us to see the internal transfers being made, so we know when products are expected to arrive at each fulfillment center. While I love working within spreadsheets, that type of modeling is rough because it isn’t updated in real-time. Using ShipBob’s real-time data and being able to see when inventory reaches the initial hub location really takes work off of our plates.”

Michael Mullaney, VP of Supply Chain at ZBiotics

For more information on how ShipBob can help your brand manage your inventory and fulfill peak order volumes, click the button below to get in touch.

Anticipation inventory FAQs

Below are answers to the most commonly asked questions about anticipation inventory.

When should a business use anticipation inventory?

A business should use anticipation inventory to meet customer demand during busy seasons, product launches or promotions, or in advance of expected supply chain disruptions.

How can ShipBob help businesses manage anticipation inventory?

ShipBob can help businesses manage their anticipation inventory with real-time inventory counts across locations and channels, as well as other inventory management tools. Our advanced analytics dashboard also provides insights needed for accurate demand forecasting, which is essential for planning anticipation inventory.

How can we reduce anticipation inventory?

The best way to reduce anticipation inventory is by being as accurate as possible with your demand forecasting. That way, you’re not stocking up on excess inventory that you don’t need.

What is ShipBob’s Inventory Placement Program?

ShipBob’s Inventory Placement Program is an inventory distribution service that allows businesses to send their entire inventory to one hub location. The program then uses a proprietary algorithm to determine the most strategic way to distribute the inventory between different fulfillment centers.

How does anticipation inventory affect cash flow and working capital?

Anticipation inventory requires buying more inventory than you currently need, which means you have some capital tied up. If you’re stocking up too much on anticipation inventory, it could limit cash flow.